Update May 2024 Management and use of cow manure from demonstration pens for the production of non-toxic crops and fodder grass (Under the university farm development project for food crop production Safe according to BCG Economic Model guidelines, year 2)

Project progress: 58%

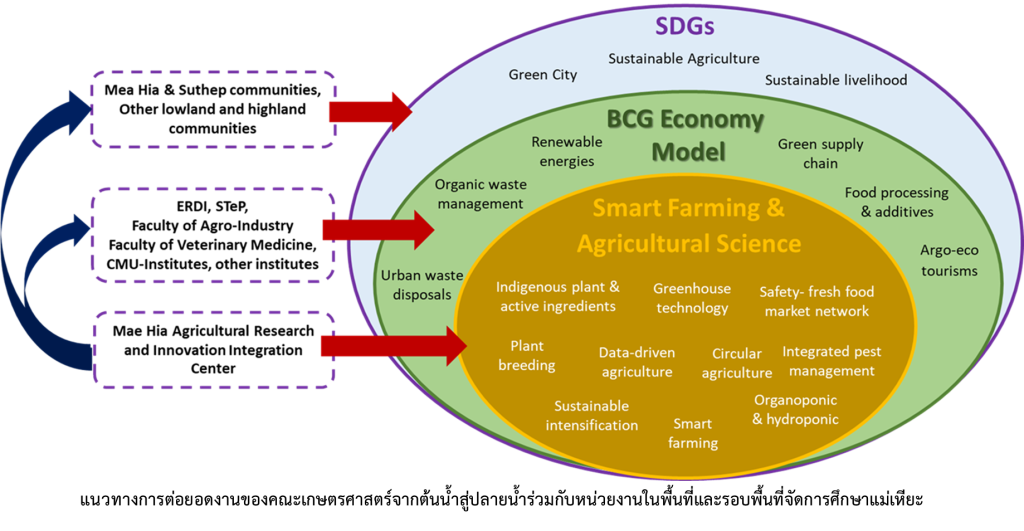

The University Farm Development Project for the Production of Safe Food Crops according to the BCG Economic Model, Year 2, was developed with the cooperation of Faculty of Agriculture Nakornping Energy Research and Development Institute Science and Technology Park Faculty of Agro-Industry and the market group for non-toxic, safe food To develop the use of space and improve activities carried out in the area of the research center. Mae Hia agriculture demonstration and training In line with the economic development guidelines according to the BCG economic model that the Thai government announced in 2018, which consists of Bioeconomy, Circular Economy, and Green Economy Bioeconomy

In the first year, the project, through the operations of the Faculty of Agriculture, has developed the use of space at the Mae Hia Agricultural Demonstration Research and Training Center. By improving the activities of the food crop production demonstration section according to the plan. Using greenhouse technology and watering systems to improve production efficiency and maintain production levels throughout the year. To produce non-toxic vegetables and healthy field crops. Production of local vegetables according to local wisdom and development of market systems There is also work in collaboration with (1) Nakornping Energy Research and Development Institute to improve the sludge obtained from biogas production from food scraps in university cafeterias to produce planting materials that can be used in crop production. and has jointly planned with (2) the Chiang Mai University Food Safety Project (Food Safety CMU) to use produce from the demonstration of non-toxic plant production as ingredients for cooking in the university cafeteria in the next phase. It is expected that the project will be able to reduce greenhouse gas emissions by 133.25 tons of carbon dioxide equivalent/year. Current project There is progress in project implementation of 58% compared to the operational plan.

Activities/Operational plans | Current operating results (8 months) |

Activity 1: Utilization of suspended sludge in biogas systems | Contract work to improve waste management systems, including installation of sludge pipes, gas cleaning systems, and various automatic control systems. and the sludge collection pond agitator set has been completed. |

Activity 2: Management of cattle barns for biogas production | Prepare a construction plan and submit it to the Planning Division for consideration, requesting a price quote and comparing equipment, and then changing the project budget item from a sewage suction truck to Sludge suction pump, area survey and work site installation of mud suction pump |

Activity 4: Operation of organizing activities | Draft of carbon reduction activities Making a tool for calculating the amount of carbon that can be reduced from carbon reduction activities. In the process of developing a tool for calculating reduction activities. on the CFE platform |